SolVision (AI Vision System)

SolVision is Solomon’s core AI vision system software designed to optimize inspection processes with our coveted deep learning technology. Utilizing machine vision and advanced algorithms, SolVision delivers exceptional performance in presence/absence checks, item classification, and defect/anomaly detection.

Compared to manual inspection and less sophisticated vision systems, SolVision stands out for its ability to reduce inspection time while ensuring increased accuracy. This allows manufacturers and producers to consistently meet the highest quality standards, resulting in enhanced overall product quality and production efficiency.

SolVision ensures effortless integration with built-in PLC communications through TCP/IP and Modbus protocols, all at no additional cost, making it the ideal vision program for systems integrators and end-users seeking an inspection automation solution. Whether in manufacturing, food processing, textiles, electronics, or other sectors, SolVision’s advanced features and deep learning capabilities cater to a diverse range of industry needs.

SolVision Features

Diverse AI Visual Inspection Applications

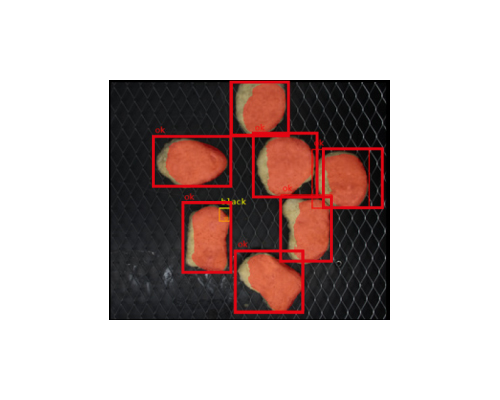

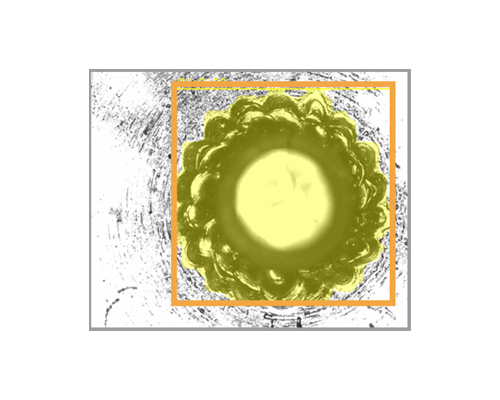

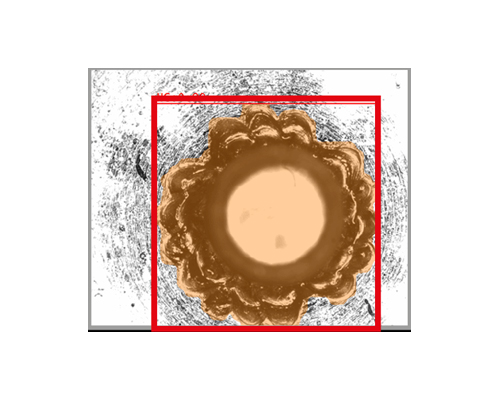

SolVision is widely recognized for its exceptional performance and versatility which allows for implementation in defect inspection, presence detection, classification, and optical character recognition applications

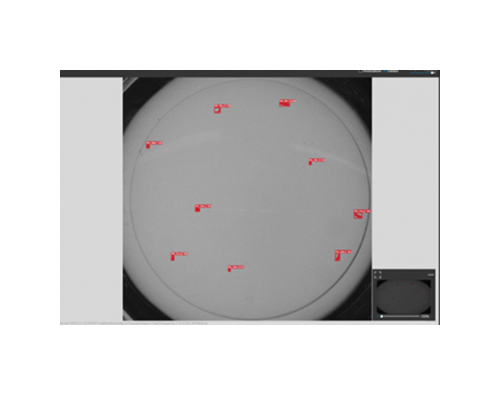

Parallel Defect Detection Capability

SolVision can leverage multiple GPUs and graphic cards to distribute the AI computing load. This capability allows users to perform multiple detections concurrently, resulting in reduced processing time and enhanced productivity.

User-Friendly Interface

SolVision has an intuitive interface that enables users to label multiple defect types simultaneously, making SolVision ideal for applications requiring the classification of several defects and features.

SolVision Applications

- Defect Detection

- Classification

- Presence/Absence

- Optical Character Recognition